Applications

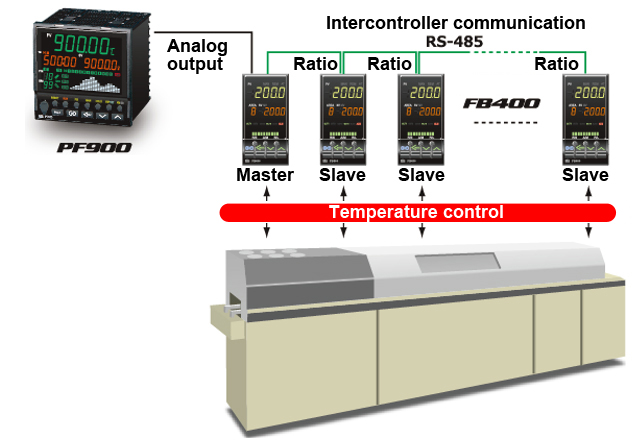

■Ratio temperature control of continuous furnace (Link operation)

Temperature program control of each zone is conducted with the preset ratio.

>>Merits of introducing this system

- Use of digital setting via communication realizes excellent reproducibility and control without setting error

- Connection via communication provides isolation between instruments.

Typical models

Program Controller (Temperature Controller)

PF900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.1 sec.

- 99 patterns x 10 segments to 10 patterns pattern by 99 segments (Max.1024 segments)

- Graphical program display

- Front loader communication

- Plug-in construction

Digital Controllers (Process and Temperature Controllers)

FB100 / FB400 / FB900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.1 sec.

- Abundant event inputs/outputs

- Loader communication

- Intercontroller Communication

- Plug-in construction