Applications

■Temperature program control of environmental test chamber

Multiple program patterns can be registered and signals to handle external sequences can be output.

>>Merits of introducing this system

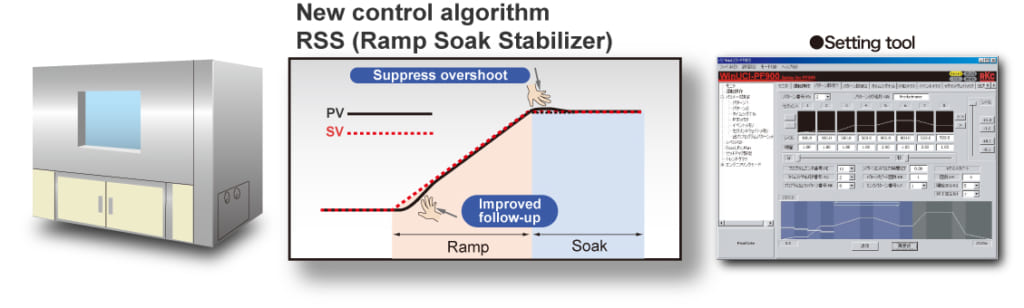

Excellent temperature program follow-up performance using new algorithm assures stability and reproducibility of the equipment.(PF900)

Combination of the loader communication and the dedicated configuration tool (software) enables easy setting of complicated program patterns.

Typical models

Program Controller (Temperature Controller)

PF900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.1 sec.

- 99 patterns x 10 segments to 10 patterns pattern by 99 segments (Max.1024 segments)

- Graphical program display

- Front loader communication

- Plug-in construction

Program Controller (Temperature Controller)

PZ400 / PZ900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.05sec.

- 16 patterns by 16 segments (Max.256 segments by linking patterns)

- 8-Level PID

- 11-segment 5-digit LCD display

- Direct access keys for easier operation

- Front loader communication port

- Plug-in construction