Products

Program Controller (Temperature Controller)

PZ400 / PZ900

- Universal Input

(Selectable from Thermocouple, RTD Pt100, Voltage, Current) - Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.05sec.

- 16 patterns by 16 segments (Max.256 segments by linking patterns)

- 8-Level PID

- 11-segment 5-digit LCD display

- Direct access keys for easier operation

- Front loader communication port

- Plug-in construction

- NEW

- Temperature

- Process

- Main features

- Main specification

- External dimensions

- Models

Main features

The current status is obvious at a glance (Large display + 3-stage display)

Various information is displayed on the large LCD.

At-a-glance monitoring of the controller.

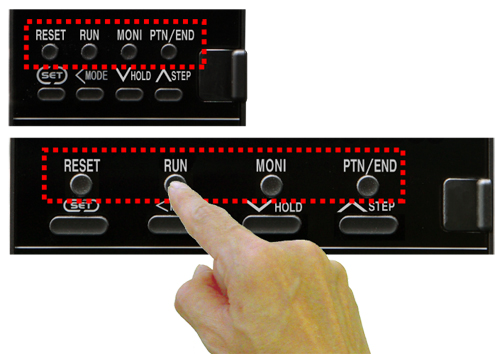

Use of direct keys simplifies the operation

Frequently used keys are assigned to the direct keys. This avoids operator’s operation errors and thus realizes easy-to-understand key operations.

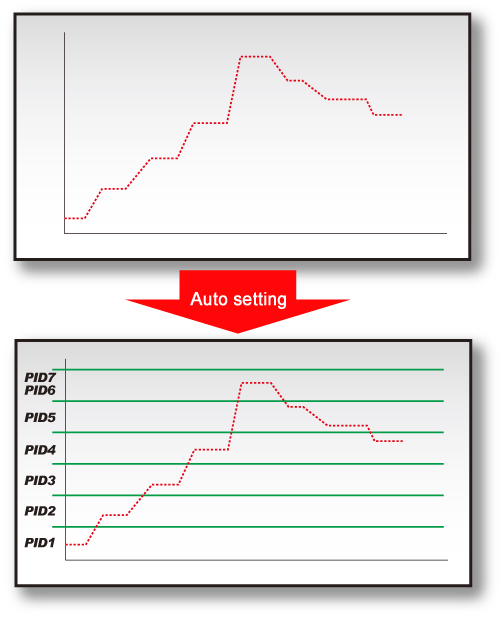

The controller adjusts setting according to the equipment to be controlled. (Level-PID automatic setting)

Level-PID function is widely used on Ramp/Soak controllers.

Level setting of each level is automatically calculated by the controller.

Without advanced knowledge, the initial setup will be automatically completed by the controller.

Front loader communication port

All models are equipped with a front loader communication port for improved maintainability Configuration data management software (PROTEM2) is available

This model can be used in advanced applications that were only handled by upper models

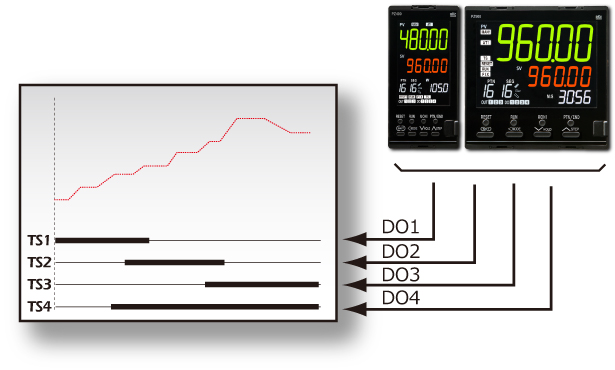

16 segments by 16 pattern The pattern link function allows setting up to 256 segments.

Up to four time signal outputs can be provided in one pattern. The use of logic operation allows setting up to 4 points per DO to handle complicated external sequences.

Please note that Shop RKC America, our online store, is exclusively available for

customers residing in the United States, Canada, and Mexico.

Main specification

- Number of Inputs : 1 point

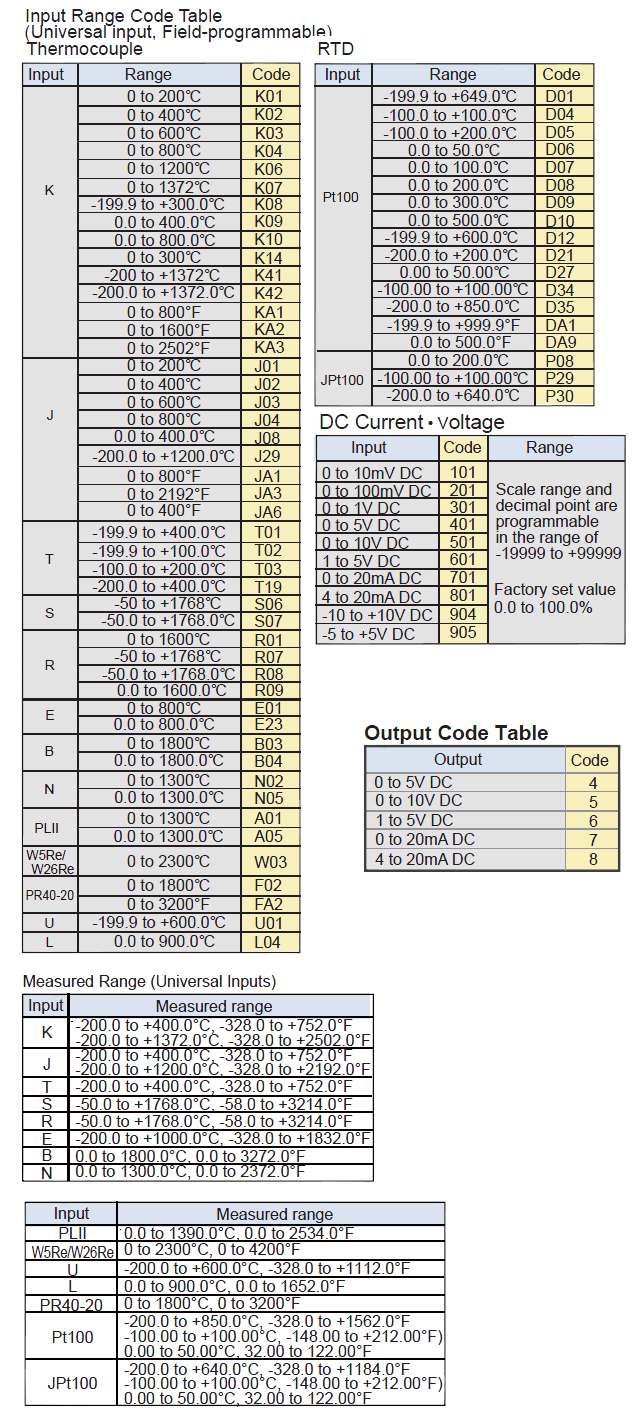

Input type (Universal input) : ※See the Input Range Code for the input range.

1) Temperature, DC current, DC voltage (low) input group

Thermocouple: K, J, R, S, B, E, N, T, W5Re/W26Re, PLII, PR40-20, U, L

RTD: Pt100 or JPt100 (3-wire type)

DC voltage (low): 0 to 10mVDC, 0 to 100mVdc

2) DC voltage input (high) group

0 to 1V, 0 to 5V, 1 to 5V, 0 to 10V, -5 to +5V, -10 to +10V

3) DC current input group

0 to 20mA dc, 4 to 20mA dc

- Sampling time: 0.05 sec.

- Measurement accuracy : ±(0.1% of displayed value+1 digit) ※Depends on the input and the

- Program control function

1) Number of program patterns: Max. 16 patterns

2) Number of program segments : Max.16 segments ※Up to 256 segments using Pattern link function

3) Segment time: 0 hour 0 min. to 199 hours 59 min. or 0 min.0 sec. to 199 min.59 sec. ※Continuous time setting possible

4) Optional functions: Remaining time display (Segment remaining time/Pattern remaining time)

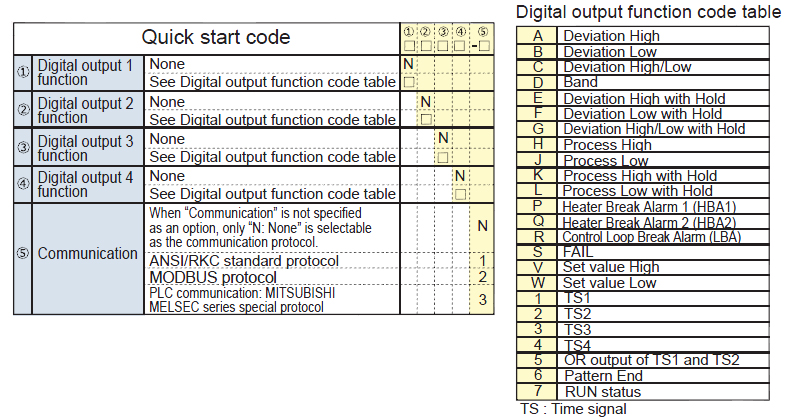

- Time signal (4 points) DO1 to 4 (DO2 to 4 are optional) : To be specified in DO assignment

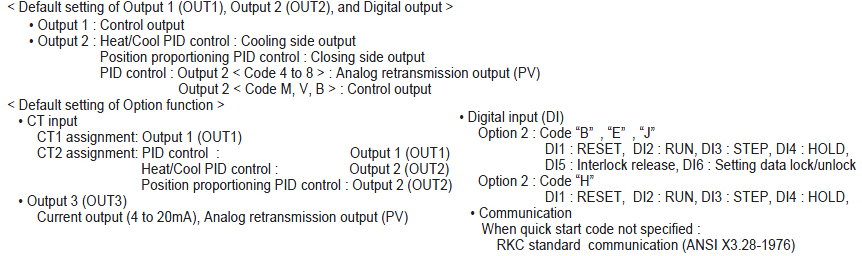

- Output 1 (OUT1) ※Control, Temperature alarm, HBA (Heater Break Alarm), LBA (Control loop break alarm), or analog retransmission can be assigned.

1) Relay contact output: 1c contact ※Highly durable relay

2) Voltage pulse for SSR driving: 0/12V dc

4) Current output: 0 to 20mA, 4 to 20mA dc

5) DC continuous voltage output: 0 to 5V, 1 to 5V, 0 to 10V

6) Transistor output: Allowable load current 100 mA

- Event function (4 points) : Assignable to OUT1 to 3, DO 1 to4

- Analog retransmission function: Analog retransmission (1 point): Assignable to OUT1 to 3.

- Loader communication : Interface RS-232C

<Specification of Options>

- Output 2 (OUT2) ※Control, Event, HBA (Heater Break Alarm), LBA (Control loop break alarm) or analog retransmission can be assigned

1) Relay contact output (a): FZ100 1a contact ※Highly durable relay

2) Voltage pulse output for SSR driving: 0/12V dc

3) Current output: 0 to 20mA, 4 to 20mA dc

4) Continuous voltage output: 0 to 5V, 1 to 5V, 0 to 10V dc

5) Transistor output: Permissible load current 100 mA

- Output 3 (OUT3) ※Universal output

※Control, Event, HBA (Heater Break Alarm), LBA (Control loop break alarm) or analog retransmission can be assigned.

1) Voltage pulse output for SSR driving: 0/14V dc

2) DC current output: 0 to 20mA, Current output : 0 to 20mA, 4 to 20mA dc

- Digital output (DO: max.4 points)

DO1 to 4: Relay contact output, 1a contact ※DO1 is supplied as standard. - Event input (Max.6 points) : RUN, RESET, Program pattern No. switching, Dir/Rev switching, HOLD/HOLD release, STEP, AT ON/OFF, Set data lock/unlock, Interlock release, Peak/Bottom hold release

- CT input for Heater break alarm: Max.2 points

- Feedback resistance (FBR), Input: 100 to 10kΩ (standard:135Ω)

- Communication: RS-422A / RS-485

<General Specification>

- Power supply voltage (Rating): 100 to 240V ac/24Vac/24Vdc

- Ambient temperature: -10 to +55°C

- Weight:

PZ400: Approx.221g

PZ900: Approx.291g

- Safety standards:

UL: UL61010-1

cUL: CAN/CSA-22.2 NO.61010-1

CE Marking:

Low Voltage Directive (LVD) EN61010-1

EMC Directive EN61326-1

RCM: EN55011

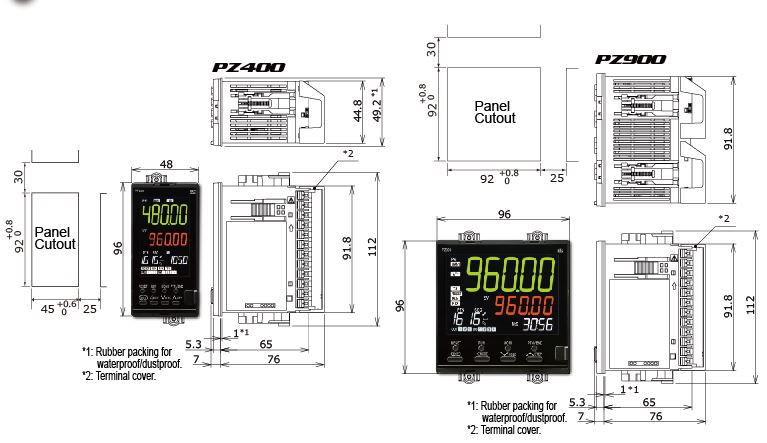

External dimensions

Unit : mm

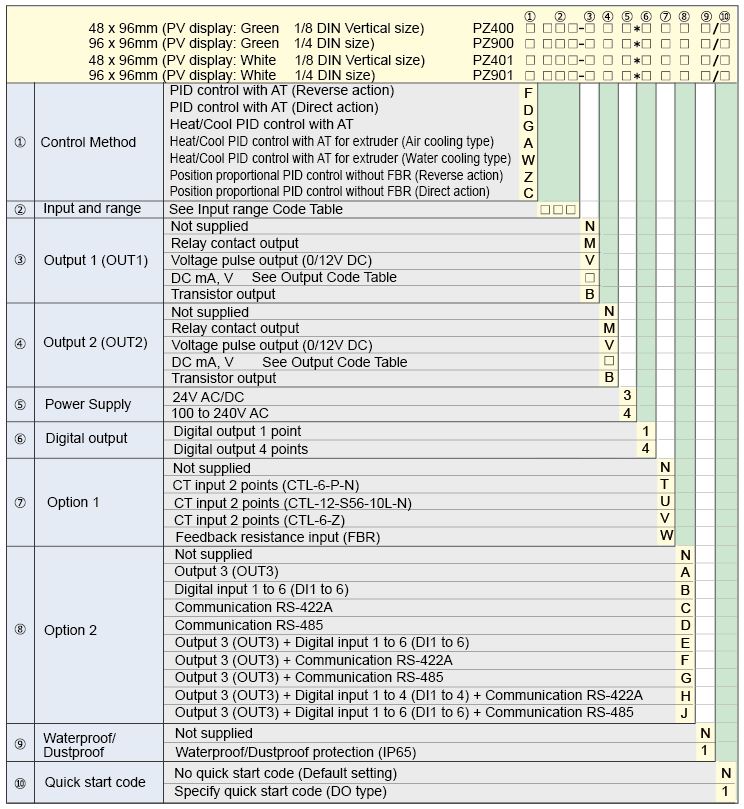

Models