Applications

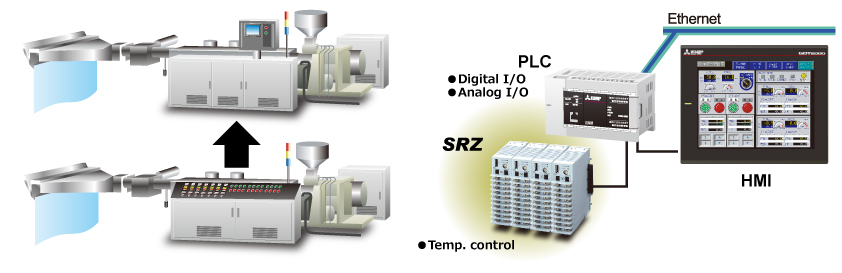

■Integrated management of extrusion lines

Control panels including temperature controllers of old extruders are retrofitted to improve efficiency.

Use of general purpose control equipment (such as a PLC and an HMI) makes replacement and extension much easier.

>>Merits of introducing this system

- Centralized management of extruders on the HMI to handle temperature control, motor drives, recipe management, alarm status/history, trend graph, etc.

- Operationality can be improved and workload can be reduced.

Typical models

Modular Controllers (Process/Temperature Controllers)

SRZ

- Measurement accuracy: ±0.2% of displayed value

- Sampling time: 0.25 sec.

- 4-channel control per module

- Front loader communication port

- Digital Input/Output and CT Input Modules

- Communication converters of various field bus communication can be connected.

Modular Controller (Process/Temperature Controller)

SR Mini HG

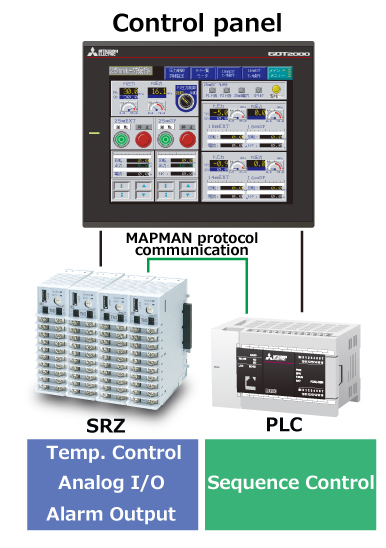

- Supplied with MAPMAN function which enables programmingless connection to a PLC.

- Measurement accuracy: ±0.3% of span (standard model), ±0.1% of span (accurate model)

- Sampling time: 0.5 sec. (standard model), 0.1 sec (accurate model)

- A wide selection of modules such as digital input/output, analog input/output, CT inputs, and temperature inputs.

Engineering of control

(HMI+PLC)

- Monitoring/Operation of a multi-loop temperature control system are placed on the HMI, enabling establishing an easy-to-manage control system.

※We can also support you to establish an overall system including a PLC.