Applications

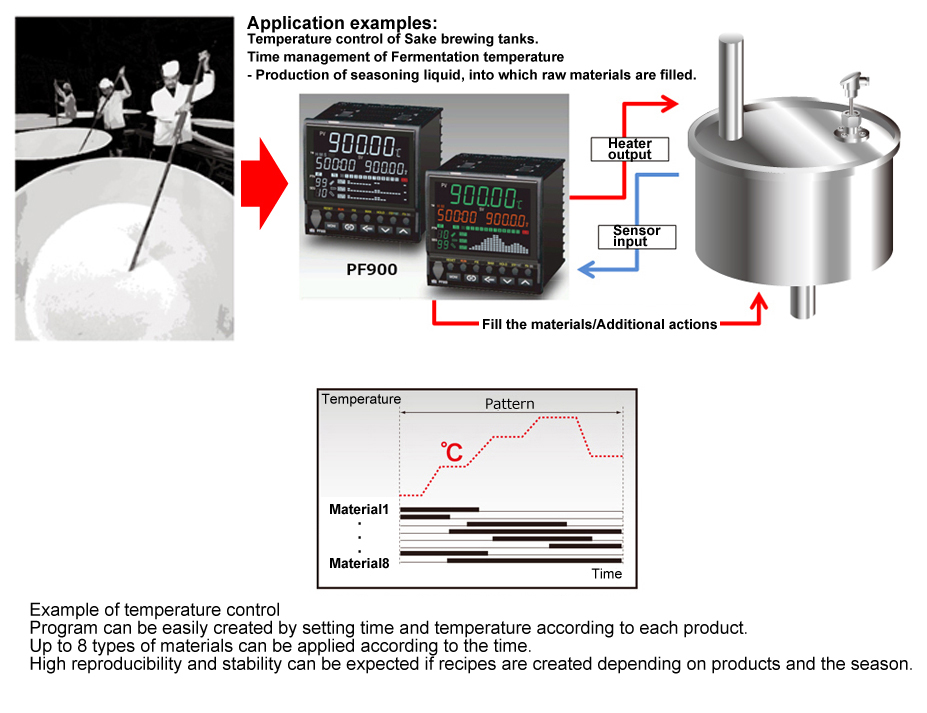

■Temperature control, fermentation time, and addition of ingredients in Sake brewery tank

Temperature control of the Sake brewery tank (program control), time management of adding various ingredients (time signal outputs) and other actions are stored in recipes and used for automatic control depending on the type of ingredients and the season.

>>Merits of introducing this system

- Variation in quality dependent on “labor skills” can be eliminated and the product quality can be uniformized.

- A series of processes including temperature setting are stored in a recipe to provide high reproducibility and stability.

Typical models

Program Controller (Temperature Controller)

PF900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.1 sec.

- 99 patterns x 10 segments to 10 patterns pattern by 99 segments (Max.1024 segments)

- Graphical program display

- Front loader communication

- Plug-in construction

Program Controller (Temperature Controller)

PZ400 / PZ900

- Measurement accuracy: ±0.1% of displayed value

- Sampling time: 0.05sec.

- 16 patterns by 16 segments (Max.256 segments by linking patterns)

- 8-Level PID

- 11-segment 5-digit LCD display

- Direct access keys for easier operation

- Front loader communication port

- Plug-in construction