Applications

■Retrofitting Extrusion Control System for Food Industries

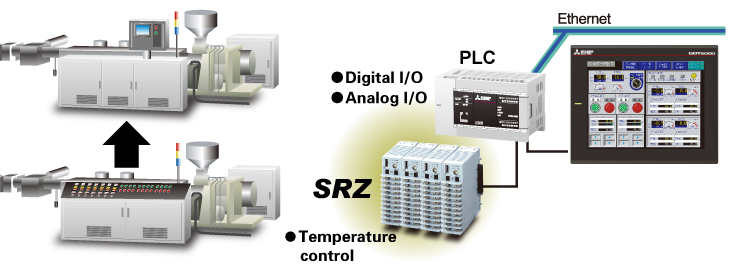

This is an updating job of the old extruder control panel including temperature controllers for improved efficiency.

Use of general purpose control equipment (such as a PLC and an HMI) makes replacement and extension much easier.

>>Merits of introducing this system

- Temperature monitoring and motor related operations are grouped on the HMI, enabling establishing an easy-to-manage control system.

- Power and communication lines are routed via connecting connectors to reduce wiring work.

Typical models

Modular Controllers (Process/Temperature Controllers)

SRZ

- Measurement accuracy: ±0.2% of displayed value

- Sampling time: 0.25 sec.

- 4-channel control per module

- Front loader communication port

- Digital Input/Output and CT Input Modules

- Communication converters of various field bus communication can be connected.

Modular Controllers (Process/Temperature Controllers)

SR Mini HG

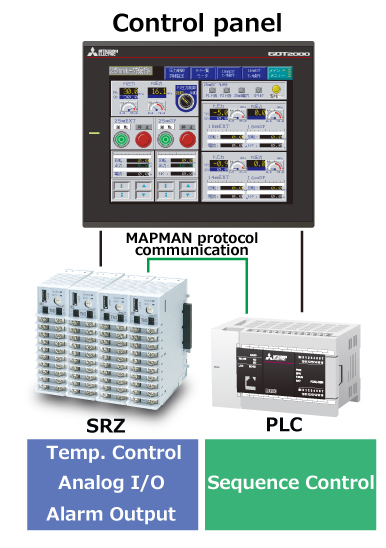

- Supplied with MAPMAN function which enables programmingless connection to a PLC.

- Measurement accuracy: ±0.3% of span (standard model), ±0.1% of span (accurate model)

- Sampling time: 0.5 sec. (standard model), 0.1 sec (accurate model)

- A wide selection of modules such as digital input/output, analog input/output, CT inputs, and temperature inputs.

Engineering of control

(HMI+PLC)

- Monitoring/Operation of a multi-loop temperature control system are placed on the HMI, enabling establishing an easy-to-manage control system.

※We can also support you to establish an overall system including a PLC.